Tiub Paip Dikimpal Keluli Tahan Karat

Penerangan

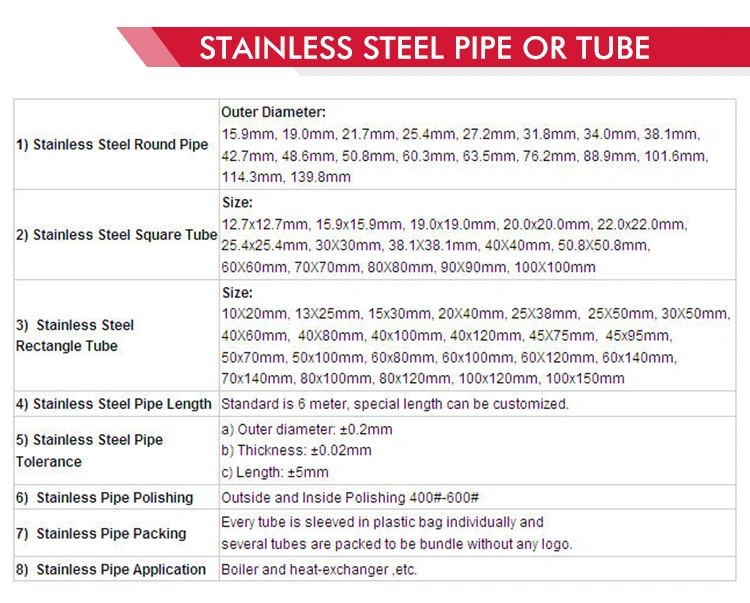

| Nama | Keluli tahan karat Lancar & Dikimpal Tiub & Paip. | ||||||

| Standard | ASTM A554,A249,A269 dan A270

| ||||||

| Gred Bahan | 201: Ni 0.8%~1% | ||||||

| 202: Ni 3.5%~4.5% | |||||||

| 304: Ni 8%, Cr 18% | |||||||

| 316: Ni 10%, Cr 18% | |||||||

| 316L: Ni 10%~14% | |||||||

| 430: Cr16%6~18% | |||||||

| Diameter luaran

| 10-1000mm | ||||||

| Ketebalan | 1-100mm | ||||||

| Panjangkan | 6m atau sebagai permintaan pelanggan | ||||||

| Toleransi | a) Diameter Luar: +/-0.2mm | ||||||

| b) Ketebalan: +/-0.02mm | |||||||

| c)Panjang:+/- 5mm | |||||||

| Permukaan | 180G,240G,320G Satin /Garis Rambut 400G, Kemasan Cermin 600G | ||||||

| Permohonan | susur tangan, pagar, tangga, skrin jaringan kimpalan, pintu, tingkap, balkoni, pagar, bangku, perabot, dll | ||||||

| Ujian | Ujian skuasy, ujian lanjutan, ujian tekanan air, ujian reput kristal, haba rawatan, NDT | ||||||

| kimia komposisi Bahan

| Komposisi bahan | 201 | 202 | 304 | 316 | 316L | 430 |

| C | <=0.15 | <=0.15 | <=0.08 | <=0.08 | <=0.035 | <=0.12 | |

| Si | <=1.00 | <=1.00 | <=1.00 | <=1.00 | <=1.00 | <=1.00 | |

| Mn | 5.5-7.5 | 7.5-10 | <=2.00 | <=2.00 | <=2.00 | <=1.00 | |

| P | <=0.06 | <=0.06 | <=0.045 | <=0.045 | <=0.045 | <=0.040 | |

| S | <=0.030 | <=0.030 | <=0.030 | <=0.030 | <=0.030 | <=0.030 | |

| Cr | 13-15 | 14-17 | 18-20 | 16-18 | 16-18 | 16-18 | |

| Ni | 0.7-1.1 | 3.5-4.5 | 8-10.5 | 10.0-14.0 | 10.0-14.0 | ** | |

| Mo | ** | ** | ** | ** | 2.0-3.0 | ** | |

| saiz tiub bulat | 12.7x1.0 , 15.8x1.2, 19.1x1.2, 25.4x1.2 | ||||||

| tiub segi empat sama | 25.4x25.4x1.2 ,25.4x25.4x2.0 , 31.8x31.8x1.2 ,38.1x38.1x1.5 | ||||||

| Tiub segi empat tepat | 40x20x1.5 , 50x25x1.5 | ||||||